|

|

| Brand Name: | BENENV |

| Model Number: | MDS301 |

| MOQ: | 1 Set |

| Price: | Negotiatable |

| Delivery Time: | 3-7 weeks |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

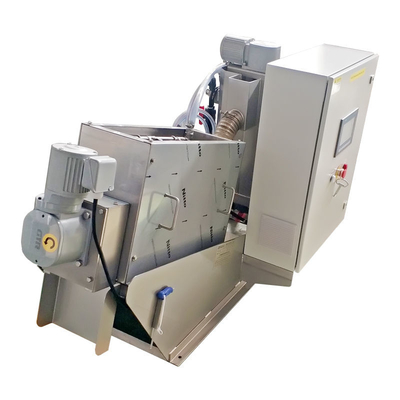

Wastewater Treament Plant Multi Disk Screw Press Sludge Dewatering Machine

|

Specifications of MDS sewage and sludge machine

|

|||

|

Main Parameters

|

Capacity

|

DS-kg/hr

|

1-600 DS-kg/hr

|

|

Size

|

mm

|

L4564*W2100*H2156

|

|

|

Power

|

kW

|

6.0

|

|

|

Motor

|

Gearbox

|

Brand

|

SEW,

SUMITOMO, NISSEI |

|

Protection

|

Certificates & IP

|

UL,CE, Water

proof(IP65) CCC

|

|

|

Screw Shaft

|

Treatment

|

SUS316L, Tungsten

carbide coating

|

|

|

Control Cabinet

|

Electrical Components

|

Brand

|

Schneider, Omron,

Siemens

|

|

Solenoid Valve

|

Brand

|

US,ASCO

|

|

|

Spray System

|

Brand

|

Japan Origin, H.IKEUCHI

|

|

![]()

![]()

![]()

![]()

![]()

|

Model

|

WAS Sludge

& Chemical Precipitated Sludge

(Thin Sludge)

|

Dissolved Air Flotation Sludge

|

Mixed Raw Sludge

Aerobic Digested Sludge

& Sewage Sludge

|

||

|

Sludge Concentration (TS)

|

0.2%

|

1%

|

2%

|

5%

|

3%

|

|

MDS 051

|

~0.4 kg-DS/hr

(0.2 m³/hr) |

~0.6 kg-DS/hr

(0.06 m³/hr)

|

~2 kg-DS/hr

(0.1 m³/hr)

|

~4 kg-DS/hr

(0.08 m³/hr) |

~5 kg-DS/hr

(0.16 m³/hr) |

|

MDS 101

|

~2 kg-DS/hr

(1.0 m³/hr) |

~3 kg-DS/hr

(0.3 m³/hr) |

~5 kg-DS/hr

(0.25 m³/hr) |

~10 kg-DS/hr

(0.2 m³/hr) |

~13 kg-DS/hr

(0.43 m³/hr) |

|

MDS 131

|

~4 kg-DS/hr

(2.0 m³/hr) |

~6 kg-DS/hr

(0.6 m³/hr) |

~10 kg-DS/hr

(0.5 m³/hr) |

~20 kg-DS/hr

(0.4 m³/hr) |

~26 kg-DS/hr

(0.87 m³/hr) |

|

MDS 132

|

~8 kg-DS/hr

(4.0 m³/hr) |

~12 kg-DS/hr

(1.2 m³/hr) |

~20 kg-DS/hr

(1.0 m³/hr) |

~40 kg-DS/hr

(0.8 m³/hr) |

~52 kg-DS/hr

(1.73 m³/hr) |

|

MDS 202

|

~16 kg-DS/hr

(8.0 m³/hr) |

~24 kg-DS/hr

(2.4 m³/hr) |

~40 kg-DS/hr

(2.0 m³/hr) |

~80 kg-DS/hr

(1.6 m³/hr) |

~104 kg-DS/hr

(3.47 m³/hr) |

|

MDS 311

|

~20 kg-DS/hr

(10 m³/hr) |

~30 kg-DS/hr

(3.0 m³/hr) |

~50 kg-DS/hr

(2.5 m³/hr) |

~100 kg-DS/hr

(2.0 m³/hr) |

~130 kg-DS/hr

(4.33 m³/hr) |

|

MDS 312

|

~40 kg-DS/hr

(20 m³/hr) |

~60 kg-DS/hr

(6.0 m³/hr) |

~100 kg-DS/hr

(5.0 m³/hr) |

~200 kg-DS/hr

(4.0 m³/hr) |

~260 kg-DS/hr

(8.67 m³/hr) |

|

MDS 313

|

~60 kg-DS/hr

(30 m³/hr) |

~90 kg-DS/hr

(9.0 m³/hr) |

~150 kg-DS/hr

(7.5 m³/hr) |

~300 kg-DS/hr

(6.0 m³/hr) |

~390 kg-DS/hr

(13 m³/hr) |

|

MDS 412

|

~80 kg-DS/hr

(40 m³/hr) |

~120 kg-DS/hr

(12 m³/hr) |

~200 kg-DS/hr

(10 m³/hr) |

~400 kg-DS/hr

(8.0 m³/hr) |

~520 kg-DS/hr

(17.3 m³/hr) |

|

MDS 413

|

~120 kg-DS/hr

(60 m³/hr) |

~180 kg-DS/hr

(18 m³/hr) |

~300 kg-DS/hr

(15 m³/hr) |

~600 kg-DS/hr

(12 m³/hr) |

~780 kg-DS/hr

(26 m³/hr) |

|

| Brand Name: | BENENV |

| Model Number: | MDS301 |

| MOQ: | 1 Set |

| Price: | Negotiatable |

| Packaging Details: | Export polywood |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

Wastewater Treament Plant Multi Disk Screw Press Sludge Dewatering Machine

|

Specifications of MDS sewage and sludge machine

|

|||

|

Main Parameters

|

Capacity

|

DS-kg/hr

|

1-600 DS-kg/hr

|

|

Size

|

mm

|

L4564*W2100*H2156

|

|

|

Power

|

kW

|

6.0

|

|

|

Motor

|

Gearbox

|

Brand

|

SEW,

SUMITOMO, NISSEI |

|

Protection

|

Certificates & IP

|

UL,CE, Water

proof(IP65) CCC

|

|

|

Screw Shaft

|

Treatment

|

SUS316L, Tungsten

carbide coating

|

|

|

Control Cabinet

|

Electrical Components

|

Brand

|

Schneider, Omron,

Siemens

|

|

Solenoid Valve

|

Brand

|

US,ASCO

|

|

|

Spray System

|

Brand

|

Japan Origin, H.IKEUCHI

|

|

![]()

![]()

![]()

![]()

![]()

|

Model

|

WAS Sludge

& Chemical Precipitated Sludge

(Thin Sludge)

|

Dissolved Air Flotation Sludge

|

Mixed Raw Sludge

Aerobic Digested Sludge

& Sewage Sludge

|

||

|

Sludge Concentration (TS)

|

0.2%

|

1%

|

2%

|

5%

|

3%

|

|

MDS 051

|

~0.4 kg-DS/hr

(0.2 m³/hr) |

~0.6 kg-DS/hr

(0.06 m³/hr)

|

~2 kg-DS/hr

(0.1 m³/hr)

|

~4 kg-DS/hr

(0.08 m³/hr) |

~5 kg-DS/hr

(0.16 m³/hr) |

|

MDS 101

|

~2 kg-DS/hr

(1.0 m³/hr) |

~3 kg-DS/hr

(0.3 m³/hr) |

~5 kg-DS/hr

(0.25 m³/hr) |

~10 kg-DS/hr

(0.2 m³/hr) |

~13 kg-DS/hr

(0.43 m³/hr) |

|

MDS 131

|

~4 kg-DS/hr

(2.0 m³/hr) |

~6 kg-DS/hr

(0.6 m³/hr) |

~10 kg-DS/hr

(0.5 m³/hr) |

~20 kg-DS/hr

(0.4 m³/hr) |

~26 kg-DS/hr

(0.87 m³/hr) |

|

MDS 132

|

~8 kg-DS/hr

(4.0 m³/hr) |

~12 kg-DS/hr

(1.2 m³/hr) |

~20 kg-DS/hr

(1.0 m³/hr) |

~40 kg-DS/hr

(0.8 m³/hr) |

~52 kg-DS/hr

(1.73 m³/hr) |

|

MDS 202

|

~16 kg-DS/hr

(8.0 m³/hr) |

~24 kg-DS/hr

(2.4 m³/hr) |

~40 kg-DS/hr

(2.0 m³/hr) |

~80 kg-DS/hr

(1.6 m³/hr) |

~104 kg-DS/hr

(3.47 m³/hr) |

|

MDS 311

|

~20 kg-DS/hr

(10 m³/hr) |

~30 kg-DS/hr

(3.0 m³/hr) |

~50 kg-DS/hr

(2.5 m³/hr) |

~100 kg-DS/hr

(2.0 m³/hr) |

~130 kg-DS/hr

(4.33 m³/hr) |

|

MDS 312

|

~40 kg-DS/hr

(20 m³/hr) |

~60 kg-DS/hr

(6.0 m³/hr) |

~100 kg-DS/hr

(5.0 m³/hr) |

~200 kg-DS/hr

(4.0 m³/hr) |

~260 kg-DS/hr

(8.67 m³/hr) |

|

MDS 313

|

~60 kg-DS/hr

(30 m³/hr) |

~90 kg-DS/hr

(9.0 m³/hr) |

~150 kg-DS/hr

(7.5 m³/hr) |

~300 kg-DS/hr

(6.0 m³/hr) |

~390 kg-DS/hr

(13 m³/hr) |

|

MDS 412

|

~80 kg-DS/hr

(40 m³/hr) |

~120 kg-DS/hr

(12 m³/hr) |

~200 kg-DS/hr

(10 m³/hr) |

~400 kg-DS/hr

(8.0 m³/hr) |

~520 kg-DS/hr

(17.3 m³/hr) |

|

MDS 413

|

~120 kg-DS/hr

(60 m³/hr) |

~180 kg-DS/hr

(18 m³/hr) |

~300 kg-DS/hr

(15 m³/hr) |

~600 kg-DS/hr

(12 m³/hr) |

~780 kg-DS/hr

(26 m³/hr) |